Standards and Tolerances

The Queensland Building and Construction Commission (QBCC) and Standards

Australia set the standards that all builders in the state must comply with when

completing work. At Civic Shower Screens & Wardrobes we always go above and

beyond the industry standard. For example, where the industry standard says,

“Imperfections like scratches, scars, and rubs should not be visible from 3 meters

away”, our work is covered under warranty should imperfections be visible from just

1 meter away.

The following guidelines aim to provide a neutral, quick, and easy reference for

customers and contractors should any issues arise.

Glass and Mirrors

We are proud to offer a 12-month warranty on our work. Scratches, fractures, chips,

or other blemishes on glass and mirrors are considered defects if caused by the

contractor and visible from a normal viewing position (see ‘Viewing and Inspecting

Distances’).

Damage that occurs after handover is not covered by warranty, nor is damage that is

caused by someone other than a Civic team member. That is why it is so important

that you point out any imperfections on glass and mirrors to a Civic team member

during handover.

Viewing and Inspecting Distances

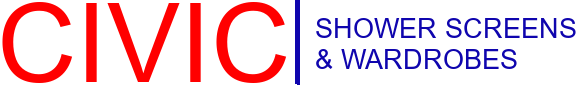

Variations in surface colour, texture, and finish, should be observed from a normal

viewing position. This diagram demonstrates the industry standard for inspecting

finished work.

Glass should be inspected vertically at a 90-degree angle under natural daylight

conditions, but not in direct sunlight. This means looking from a distance of 1 metre

or greater, with the surface or material illuminated by “non-critical light.”

Imperfections like scratches, scars, and rubs should not be visible from 1 metre

away, and the maximum allowable imperfections must comply with those outlined in

this document. Please note that slight variations in colour and finish do not constitute

a defect.

Dimensional Tolerances

| Glass Types 4 and 6 Annealed or Tempered Glass | ||

|---|---|---|

| Thickness | Range | |

| 4mm | 3.5 – 4.5 | |

| 5mm | 4.5 – 5.5 | |

| 6mm | 5.5 – 6.5 | |

| 10mm | 9.0 – 10.8 | |

| Length/width tolerance for glass under 1200mm | Glass thickness 3,4,5, & 6 | Glass thickness 8, 10 & 12 |

| ± 3mm | ± 3mm | |

| Length/width tolerance for glass over 1200mm | Glass thickness 3,4,5, & 6 | Glass thickness 8, 10 & 12 |

| ± 3mm | ± 3mm | |

| Squareness |

Difference in diagonals 5 max. for panels with largest dimension less than 1200 Difference in diagonals 10 max. for panels with largest dimension greater than 1200 |

|

The standard nominal thickness and thickness tolerances apply to common glass thicknesses and common manufacturing tolerances for float glass, laminated glass, laminated float glass, patterned glass and wired glass.

Glass Flatness

Industry standards for glass flatness are listed below.

| Glass Thickness | Horizontal Glass Dimension 1501 to 3000mm | |

|---|---|---|

| Thickness | Range | |

| 6mm | 1 in 250 | |

| 10mm | 1 in 300 |

It’s important to note that at Civic we aim to always exceed industry standards, for

example:

On 6mm thick glass with a 2000mm horizontal dimension, industry standard allows

for up to 8mm bow. Civic would deem the glass defective with only a 4mm bow.

That’s half the industry standard!

Glass Quality

| Blemish Type | Blemish size and limit of frequency |

|---|---|

| Glass types 4 and 6 up to 2.5 m2 | |

|

Bubbles and Inclusions < 1.0mm 1.0mm – 5.0mm > 5.0mm |

No limit 2 Nil |

| Stains | Nil |

| Scratches, scars and rubs | Imperfections shall not be visible from a distance of 3m. |

|

Edge quality - Shells / flanges - Broken corners and corners on/off - Vented edges - Shark’s teeth |

Max size equal to glass thickness Nil Nil Less than 100% of glass thickness with no venting |

| Surface vent | Nil |

| Surface blisters | Nil |

| Process surface imperfections | Imperfections shall not be visible from a distance of 3m. |

| Glass greater than 6.0 mm in thickness may contain proportionally more and larger imperfections. | |

| Heat-strengthened and toughened glass may be subjected to spontaneous fracture due to the presence of inclusions such as nickel sulphide, silicones, and the like even when such inclusions are smaller than those allowed in the table above. We apply proprietary testing methods to minimize the presence of such inclusions. | |

It’s important to note that at Civic we aim to always exceed industry standards, for

example:

On 6mm thick glass with a 2000mm horizontal dimension, industry standard allows

for up to 8mm bow. Civic would deem the glass defective with only a 4mm bow.

That’s half the industry standard!

Noticed a Defect?

- Document the Issue: Clearly document the defect with photos and/or videos.

- Email Your Documentation: Send your documentation and a short message explaining the issue to warranties@civicscreens.com.au. Include the address, builder, approximate date of the install, your name, and contact information in your message.

- Review: One of our team members will review your email and get back to you as soon as possible.

Glossary

Bow

A deviation from straightness or flatness in the glass.

Bubble

A gas-filled cavity within the glass. If close to the surface, it may appear as an "open" bubble, forming a hemisphere at the surface. Bubbles can be spherical or elongated and are also known as blisters or seeds.

Chip

A small, shallow blemish left at the edge of the glass after a piece has fallen out.

Corners on/off

A nib located on or near the corner of a glass sheet.

Distortion

Undulations in the glass cause objects to appear distorted or wavy when viewed through the glass.

Edge Quality

Defects along the edge of the glass, including vents, shells, flakes, chips, waves, shark’s teeth, nibs, and corners on/off.

Flange

A bevel-like protrusion above the cut edge, distinct from a corner "on" due to its often razor-sharp edge.

Inclusion

A crystalline or non-crystalline particle trapped within the glass.

Nib

A section of glass remaining on or removed from the edge of a sheet, caused by an incomplete score mark that doesn't reach the traverse mark.

Process Surface Imperfections

Minor surface flaws originating from the manufacturing process, such as small particles of foreign materials or surface irregularities.

Rub

An abrasion on the glass surface that produces a frosted appearance, differing from a scratch by its appreciable width.

Shark's Teeth

Prominent features on the cut edges, extending from the score mark through part or all of the glass thickness.

Scar

A scratch on the surface of the glass.

Scratch

Any marking or tearing of the surface occurring during manufacturing or handling, appearing as if caused by a sharp or rough instrument.

Shell

Similar to a chip but typically larger and occurring on the face opposite the score mark.

Stain

Degradation of the glass surface due to the presence of other chemicals, such as concrete splash. Stains may be difficult to detect unless the glass is silvered or coated with ceramic paint.

Vented Edges

Cracks that run inward from the edge of the glass.

Vented Inclusion

A crack in the glass surface caused by the presence of an inclusion.

Sources

Information provided in this document is sourced from the following official industry regulations:

Sections 1.4 and 18.3 of the QBCC Standards and Tolerances Guide

https://www.qbcc.qld.gov.au/resources/guide/standards-tolerances-guide

The Australian/New Zealand Quality Requirements for Cut-to-Size and Processed

Glass

https://www.standards.org.au/standards-catalogue/standard-details?designation=as-nzs-4667-2000

Download printable version

For more information please get in touch!