This scope is based on the Australian/New Zealand AS/NZS 4667:2000 and our supplier guidelines.

-

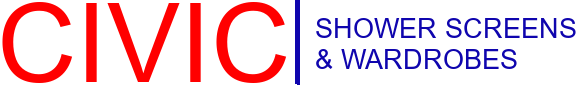

VISIBLE INSPECTION GUIDELINES

Glass is to be inspected at an angle perpendicular (90 degrees) to the surface and viewed under natural light (not in direct sunlight or under bright lighting). The glass is to be inspected from a viewing distance of 3 metres, looking through the glass to a point 1 metre behind it. (Note: the general purpose of glass is to be looked through, not at.) The above applies to mirrors in that they are designed for viewing a reflection, not focusing on the surface. Glazing within the first 12 months from completion of the work — scratches, fractures, chips or blemishes caused by the contractor and visible from a normal viewing position as per Figure 1.4 — are considered defects. -

CENTRAL VIEWING AREA

The central viewing area is defined as the area which you would normally look through or at. This area comprises a rectangle or square whose dimensions do not exceed 80% of the height, with a minimum edge border of 75mm. All other areas are considered non-viewing areas. -

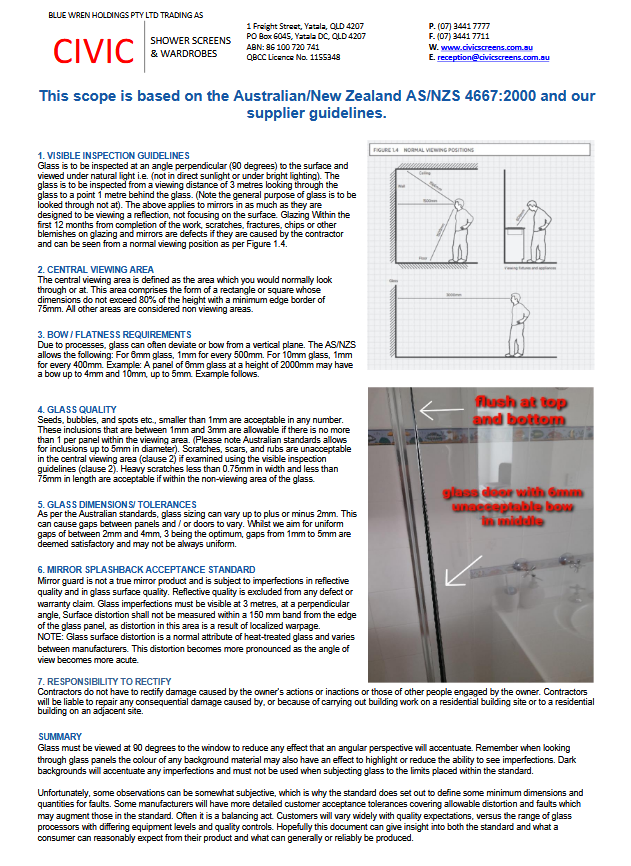

BOW / FLATNESS REQUIREMENTS

Due to processes, glass can often deviate or bow from a vertical plane. The AS/NZS allows the following: For 6mm glass, 1mm for every 500mm. For 10mm glass, 1mm for every 400mm. Example: A panel of 6mm glass at a height of 2000mm may have a bow up to 4mm and 10mm, up to 5mm. Example follows -

GLASS QUALITY

Seeds, bubbles, and spots etc., smaller than 1mm are acceptable in any number. These inclusions that are between 1mm and 3mm are allowable if there is no more than 1 per panel within the viewing area. (Please note Australian standards allows for inclusions up to 5mm in diameter). Scratches, scars, and rubs are unacceptable in the central viewing area (clause 2) if examined using the visible inspection guidelines (clause 2). Heavy scratches less than 0.75mm in width and less than 75mm in length are acceptable if within the non-viewing area of the glass. -

GLASS DIMENSIONS/ TOLERANCES

As per the Australian standards, glass sizing can vary up to plus or minus 2mm. This can cause gaps between panels and / or doors to vary. Whilst we aim for uniform gaps of between 2mm and 4mm, 3 being the optimum, gaps from 1mm to 5mm are deemed satisfactory and may not be always uniform. -

MIRROR SPLASHBACK ACCEPTANCE STANDARD

Mirror guard is not a true mirror product and is subject to imperfections in reflective quality and in glass surface quality. Reflective quality is excluded from any defect or warranty claim. Glass imperfections must be visible at 3 metres, at a perpendicular angle, Surface distortion shall not be measured within a 150 mm band from the edge of the glass panel, as distortion in this area is a result of localized warpage. NOTE: Glass surface distortion is a normal attribute of heat-treated glass and varies between manufacturers. This distortion becomes more pronounced as the angle of view becomes more acute. -

RESPONSIBILITY TO RECTIFY

Contractors do not have to rectify damage caused by the owner’s actions or inactions or those of other people engaged by the owner. Contractors will be liable to repair any consequential damage caused by, or because of carrying out building work on a residential building site or to a residential building on an adjacent site. -

SUMMARY

Glass must be viewed at 90 degrees to the window to reduce any effect that an angular perspective will accentuate. Remember when looking through glass panels the colour of any background material may also have an effect to highlight or reduce the ability to see imperfections. Dark backgrounds will accentuate any imperfections and must not be used when subjecting glass to the limits placed within the standard.

Unfortunately, some observations can be somewhat subjective, which is why the standard does set out to define some minimum dimensions and quantities for faults. Some manufacturers will have more detailed customer acceptance tolerances covering allowable distortion and faults which may augment those in the standard. Often it is a balancing act. Customers will vary widely with quality expectations, versus the range of glass processors with differing equipment levels and quality controls. Hopefully this document can give insight into both the standard and what a consumer can reasonably expect from their product and what can generally or reliably be produced.

Download printable version

For more information please get in touch!